Training Within Industry

Training Within Industry is a leadership development program designed specifically for front-line leaders operating within an industrial setting. Its tried-and-true approach has a long history of success.

The Training Within Industry Service (TWI) was established in 1940 to help with the increased production needed to support the Allied Forces during World War II. The three programs, known as the “J” programs, had a major positive impact on manufacturing output in the U.S. during the war.

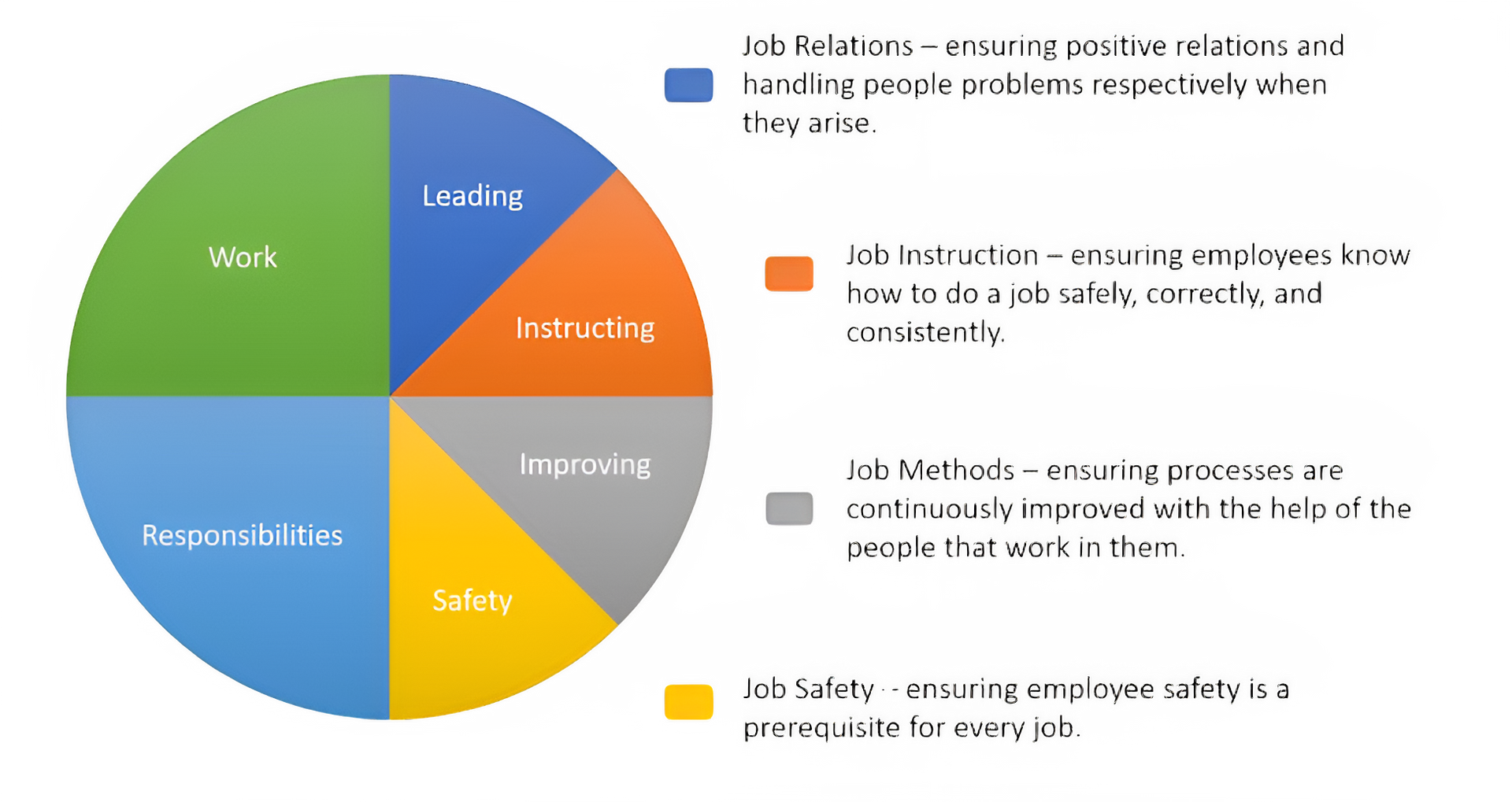

In its short 5-year existence, TWI was implemented in over 600 companies that, on average, experienced a 60% improvement in productivity. The “J” programs are:

Each “J” focuses on the relationship between supervisors (anyone who directs others' actions) and employees. After the war, the programs began to wind down in the U.S. It was recognized that Japan needed support in rebuilding their industrial infrastructure. The programs developed by the TWI Service were deployed to help them accomplish the goal.

Rediscovery

After the war, TWI faded from use in the U.S. For the past ten years, organizations have rediscovered TWI as a foundation for creating operational excellence and transforming their culture. KPC thinks we’ve played a small part in TWI’s resurgence. We have helped many of our clients take operational excellence to the next level by introducing TWI into their organizations using our dynamic hands-on learning and practice program. For many organizations, the results are:

- A safer and more productive workplace

- Higher levels of cooperation and positive employee relations

- Reduced process variation through standardized training

- Reduction in job learning curves

- Effective problem-solving at the shop floor level

Our Approach

Organizations often implement TWI piecemeal, implementing only one or two J programs (Job Instruction is the most popular). This is due to a misunderstanding of the underlying intent of TWI. Training Within Industry is a system, and the J programs are designed to reinforce each other. It is the intersection and interaction of the J programs that ultimately ensure the success of TWI. Adding to the misunderstanding is that TWI was a 'wartime' intervention, and due to that sense of urgency, many of the soft skills required in the present-day workplace are not addressed.

At KPC, we recognize the power of TWI as a cultural change system and the need to enhance the original system with the people skill competencies needed to be effective in today's workplace. Our holistic approach to TWI implementation ensures sustainable results.

Take Action Today

Ready to Take the Next Step?

Contact us today with any questions!

Contact Us

Frequently Asked Questions

Why is Key Performance Consulting so popular?

Key Performance Consulting has earned its popularity through our exceptional business consulting services tailored specifically for small and mid-sized organizations. Based in Charles City, we are dedicated to helping businesses achieve enterprise excellence by providing customized training, coaching, and consulting offerings. Our approach to business consulting services involves understanding how your organization makes money, the challenges it faces, and the goals it strives to achieve. With a unique blend of Lean Enterprise, Lean Six Sigma, and our extensive manufacturing experience, we provide results-focused business consulting services that help you reduce waste, enhance productivity, and improve your bottom line. Standing out in Charles City, our business consulting services empower your organization to stay competitive and efficient. Experience the difference in our business consulting services today with Key Performance Consulting and elevate your business to new heights.

Where can I find business consulting services in Charles City?

If you are searching for top-tier business consulting services in Charles City, look no further than Key Performance Consulting. We pride ourselves on providing comprehensive solutions tailored to meet your organization's unique needs. Our expert team stands ready to help streamline and optimize your business operations. Let's discuss how we can assist your company!

What are the benefits of process improvement in business?

Process improvement is crucial for any business looking to stay competitive and efficient. By analyzing and optimizing workflows, businesses can reduce waste, increase productivity, enhance safety, and ultimately improve profitability. Key Performance Consulting specializes in identifying improvement opportunities and implementing effective solutions. Discover the advantages of enhancing your processes with us!

How can lean leadership development benefit my organization?

Lean leadership development teaches and coaches leaders to efficiently manage a lean environment. This expertise fosters a culture of continuous improvement, enabling your organization to operate more efficiently and achieve long-term success. At Key Performance Consulting, we provide the support and resources necessary for developing effective lean leaders. Transform your leadership approach with our expert guidance!

What is Value Stream Mapping, and how does it help my business?

Value Stream Mapping is a visual tool that allows you to map the production flow and highlight improvement areas. It helps businesses identify inefficiencies, streamline operations, and increase productivity by providing a clear view of current and future states. Enhance your business processes with Key Performance Consulting's expertise in Value Stream Mapping. Contact us today for more details!

Why choose Key Performance Consulting for staff training?

Our staff training programs are designed to equip your team with the skills and knowledge necessary for achieving continuous improvement and operational excellence. By tailoring our training initiatives to your specific organizational needs, we ensure impactful outcomes. Let Key Performance Consulting empower your workforce for better performance. Get in touch to learn more!